Video featuring FSB and Rosin Preservation: Restoration Efforts at the Oklahoma State Capitol

For more information about Oklahoma State Capitol restoration, visit: http://www.CapitolRestore.ok.gov

Video featuring FSB and Rosin Preservation: Restoration Efforts at the Oklahoma State Capitol

For more information about Oklahoma State Capitol restoration, visit: http://www.CapitolRestore.ok.gov

During the next few weeks, American Airlines workers will be moving equipment and tooling into the facility while contractors finish interior offices, break rooms and bathrooms. Mechanics are expected to begin maintaining, repairing and overhauling airplanes in the fabric-covered hangar in November, American executives said.

“We’re going to have two (Boeing) 757 MAUI lines in the new hangar by the end of the year,” said Carmine Romano, American’s senior vice president of maintenance and engineering.

“It gives us two bays for widebodies that we would not otherwise be able to do in Tulsa and (facilities for) close to 200 people, including production supervisors.”

American’s MAUI — Mid-life Avionics Upgrade Initiative — on its 124-aircraft 757 fleet should occupy the new hangar through 2011, Romano said. American mechanics in the MAUI program are overhauling the 757’s computers, flight control systems, cockpit liquid crystal display monitors and flight recorders to increase system capacity and capabilities. Hangar No. 80, as American’s new facility has been named by the Tulsa Airport Authority, is 370 feet long, 220 feet wide, with a ceiling height of 70 feet. Its door opening is 190 feet wide by 66 feet high.

The hangar is the first constructed in the airport’s North Development Area, which is connected to American’s main facilities by a series of taxiways. The hangar is a clear-span structure with no interior supporting columns, allowing efficient use of space. Its white translucent roof sheds much of the heat of the sun but admits so much light on sunny days that electrical lighting won’t be needed in many areas.

Manufactured by Rubb Inc., Sanford, Maine, a U.S. subsidiary of the Rubb Group of Bergen, Norway, the building is constructed of a galvanized steel frame. The frame is covered by a woven polyester fabric coated with polyvinyl chloride, which imparts strength and waterproofing to the fabric. From a distance, Hangar 80 appears to be constructed of sandstone-colored adobe. Up close, the walls of the hangar look like stiff, rugged burlap.

“The Rubb hangar is typically 40 percent less expensive to build than a conventional pre-engineered steel, aluminum, wood or fiberglass hangar”, said Gordon Collins, director of marketing for Rubb Inc.

“The (steel) structure will last 40 to 50 years with little or no maintenance,” Collins said. “The (polyester fabric) membrane is expected to last 20 to 25 years with no maintenance, either. At the end of the life of the membrane, you simply replace it. The cost of replacing the membrane is 20 percent of the purchase price of the original building installed.”

Another feature of Hangar 80 is it is relocatable. The steel framing and fabric membrane were transported from Maine to Tulsa on flatbed trucks. “There will be significant (cost) savings with our building,” Collins said.

Coming up with the cash

Conserving cash and reducing costs have been a mantra at American Airlines since its near-bankruptcy in 2003. But by 2006, American executives could see the company’s aircraft maintenance organization was headed for a wall. At American’s 3.3-million-square-foot Tulsa Maintenance & Engineering Center as well as maintenance bases in Fort Worth and Kansas City, hangar space was disappearing faster than airline meals.

Besides maintaining its own fleet, American had begun to solicit third-party aircraft maintenance, further constraining its hangar capabilities, particularly for widebody jets.

“We needed another widebody facility,” Romano said.

It was a stark choice: build a widebody hangar in Tulsa, or risk losing the work and jobs to another city, said leaders at American and Transport Workers Union Local 514. But with the airline industry still in a post-9/11 financial dive, American couldn’t afford to invest in buildings it couldn’t own. All of the facilities at the M&E Center are owned by the City of Tulsa and leased to AMR Corp., American’s parent.

“We went to the city and asked for help for our widebody fleet,” said Kevin Crosser, an American mechanic and an executive board officer at Local 514. “The city stepped up. The voters and the community wanted to make sure American Airlines stayed in Tulsa and that the jobs stayed in the community.”

With the passage of the third-penny sales tax extension in May 2006, Tulsa voters approved $463.4 million for capital improvements, including $4.3 million in infrastructure at Tulsa International Airport. A year later, Gov. Brad Henry tapped the state’s Opportunity Fund, an economic development account, for $10 million to help preserve aerospace jobs in Tulsa. Mayor Kathy Taylor paired $4.3 million from the third-penny sales tax with $5.7 million from the Opportunity Fund to build American a new widebody hangar.

“This is the next step in further solidifying Tulsa’s leadership in the aerospace industry,” Taylor said in announcing the city-state funding partnership in May 2007.

“Our investment in jobs and our investment in education will ensure a bright future for Tulsa.”

The remaining $4.3 million from the state Opportunity Fund was spent to remediate Building 119, which had been contaminated with hazardous chemicals, for Spirit AeroSystems Inc. The cleanup at Building 119 has given Spirit additional space and created more jobs in its government and commercial aircraft component manufacturing programs, company executives said. American and city officials were aware $10 million wouldn’t go far in constructing conventional aircraft hangars. And American’s 330 acres at Tulsa International didn’t have room for a widebody hangar. But to the west, beyond the airport’s 10,000-foot north-south runway, was a couple hundred acres of bare land in the North Development Area connected to the M&E Center by taxiways.

In conversations with city and state officials, Romano praised the three-sided fabric hangar built by Rubb Inc. at the M&E base a decade ago.

“The same company built a hangar on the west side that we use for engine changes,” Romano said. “It’s worked out well for us.”

Early reviews by American executives are that the new hangar will be as efficient and cost-effective as the first Rubb hangar.

“We have two years of chock-to-block-full facilities for aircraft maintenance and modifications,” Romano said.

American Airlines’ Tulsa Maintenance & Engineering Center

Established: 1946

Area: 330 acres; 3.3 million square feet of hangar, shop and office space.

Employment: 6,600 aircraft mechanics and related work groups

Hangars: 135,000 square feet each in Hangars 1, 2, 3 and 4; Hangar 5: 215,000 square feet; Hangar 6: 341,000 square feet; 240,000 square feet of shop space between Hangars 1 and 2 and between Hangars 3 and 4; relocatable hangar: 81,400 square feet

Capabilities: airframe repair, overhaul and modification; maintenance and repair of landing gear, wheel, brakes; maintenance of General Electric, Pratt & Whitney and CFm engines; avionics overhauls; composite repairs and parts manufacturing

Estimated 2009 purchases from local vendors and suppliers: $74 million

2009 maintenance budget: $2.2 billion.

Source: Amr Corp., American Airlines

American Airlines’ Hangar 80

Size: 81,400 square feet.

Site: 8.5 acres, North Development Area, Tulsa International Airport.

Dimensions: 370 feet long, 220 feet wide, 74.5 feet high; door opening: 190 feet wide, 66 feet high.

Under roof maintenance capabilities: one Boeing 767, one Boeing 737; two 737s; two Boeing 757s; or two Boeing MD-80s.

Work force: 200 mechanics, technicians, cleaners and production supervisors.

General contractor: The Ross Group, 333 W. Fourth St.

Building materials supplier: Rubb Inc., Sanford, Maine.

Owner/lessor: Tulsa Industrial Authority.

Source: AMR Corp., American Airlines; Tulsa Airport Authority.

Oklahoma State University – Bert Cooper Lab Construction Time Lapse: January 22, 2014 through January 23, 2015

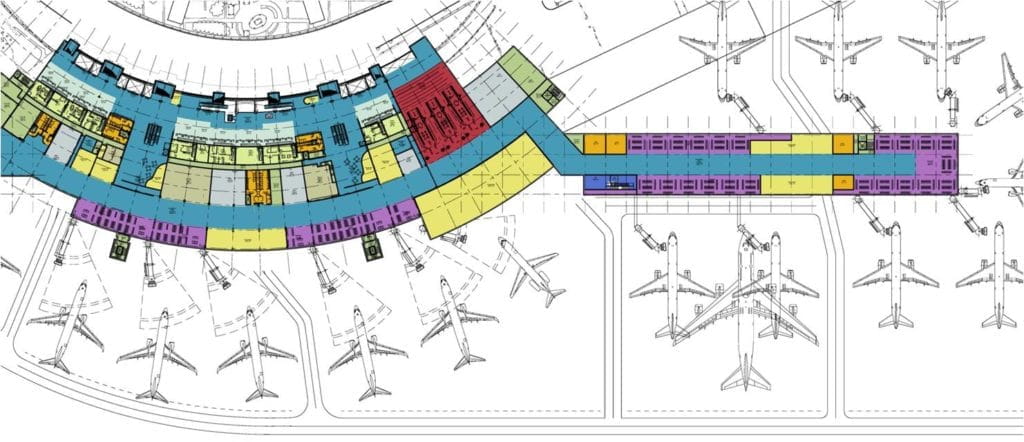

The schematic design was recently approved by Oklahoma City Airport Trust and hopes to increase the terminal’s capacity. As of now, the airport has only one gate that is available to lease, which leaves little room for additional airlines. Having only one leasable gate is also preventing current carriers from increasing their capacity.

“The design will enable the airport to attract new airlines and reintroduce international travel, expanding its destinations and placing Oklahoma City on the map of the world’s top airports” said Will Jenkinson, vice president and regional leader of HOK’s Aviation + Transportation practice.

The project will introduce additional retail outlets, dining amenities, high-tech upgrades, new baggage claim seating, four new gates, and space for six more gates and future international air service. An improved and expanded security checkpoint will be added to adhere to new Transportation Security Administration modes of operation. A new public observation gallery and suspended deck will also provide lounge space with concourse views. Newly added skylights and larger windows will provide more natural light throughout the concourse, where public art installations will be prominently featured.

You’re likely to see just about anyone there, including policymakers, CEOs and average Joes – and Flaming Lips frontman Wayne Coyne’s nephew checks people in at the front desk. The building is a bustling hub of activity day and night as people come in droves to work out, swim, run, play basketball and take yoga classes. Copious natural light spills throughout the center’s large transparent open spaces and a gymnasium with an elevated running track is lit by a huge skylight.

You’re likely to see just about anyone there, including policymakers, CEOs and average Joes – and Flaming Lips frontman Wayne Coyne’s nephew checks people in at the front desk. The building is a bustling hub of activity day and night as people come in droves to work out, swim, run, play basketball and take yoga classes. Copious natural light spills throughout the center’s large transparent open spaces and a gymnasium with an elevated running track is lit by a huge skylight.

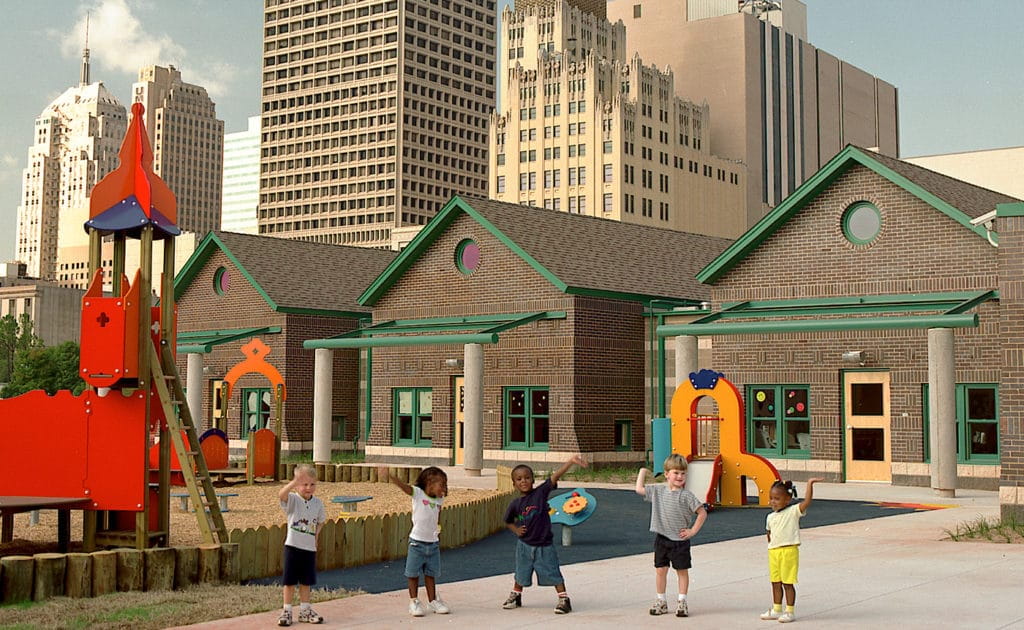

The spot has become a gathering place in downtown where adults work out and children across a courtyard in the child development center learn and grow together. The fitness building was completed in 1999 in conjunction with a project that included renovation of the old OPUBCO building at 500 N. Broadway Ave.

Fred Schmidt, principal and partner with the architectural and engineering firm Frankfurt-Short-Bruza Associates, was already involved in the renovation of the historic newspaper building when tragedy struck. The bombing of the Alfred P. Murrah federal building in 1995 not only destroyed that building, but also damaged others, including the nearby Downtown YMCA. The Gaylord family, the owners of OPUBCO, donated the newspaper building and the rest of the block to the east of that building for a new YMCA.

An existing building was torn down and work began in the late 1990s on a new YMCA and a child development center. The YMCA and the architects sought input from members, and potential members, on the look and feel of the fitness building.

“That feedback defined the project,” Schmidt said. Schmidt said the design is unique and cutting-edge for a YMCA. “A lot of people are really impressed,” he said. “They walk in and say ‘is this a YMCA?’”

The 37,000-square-foot fitness center was built for $5.1 million. It looks east and faces the $1.3 million child development center completed in late 1998. When it came time Schmidt and his team knew they had to design something special, knowing what the child development center was replacing. “It was pretty emotional because it was tied to the worst disaster Oklahoma City has ever seen,” he said.

The final product has a residential feel with each classroom set up as a house complete with a gabled porch and two pillars of Oklahoma cedar at each door. Ceiling tiles in the hallways are cut into cloud patterns and many windows are lowered so that children do not have to crane their necks for a look outside. All of the connected rooms open onto a central playground.

“The YMCA wanted the architectural environment to support children’s learning potential,” Schmidt said.

The goal of the project was to look toward a bright future, create a gathering spot downtown, and not focus on the tragic events that brought about the new buildings in downtown Oklahoma City.

“This was a brand-new start,” Schmidt said.

AAR and the City of Oklahoma City Department of Airports today jointly announced the opening of a new state-of-the-art Fixed Base Operation (FBO) corporate and general aviation facility at Will Rogers World Airport that will be capable of handling more than 10,000 flight operations annually.

AAR and the City of Oklahoma City Department of Airports today jointly announced the opening of a new state-of-the-art Fixed Base Operation (FBO) corporate and general aviation facility at Will Rogers World Airport that will be capable of handling more than 10,000 flight operations annually.The opening of the 1.8 million, 6,000-square-foot facility is the culmination of a unique public/private partnership between AAR and Oklahoma City designed to provide corporate and general aviation customers with a modern business terminal and an inviting gateway to the city’s business district and other attractions.

“We believe the modernization of the FBO facility shows what can be accomplished when the public and private sectors join forces for the greater good of the community,” said the Honorable Mick Cornett, Mayor of the City of Oklahoma City. “Thanks to the strong collaboration between the Department of Airports and AAR, we can now offer visitors a first-class aviation facility that reflects Oklahoma City’s efforts to stimulate and support our local economy.”

“The new, modernized facility will provide visitors with an impressive gateway to the city and a great experience for clients and the flight crew,” said David P. Storch, Chairman and Chief Executive Officer of AAR CORP. “AAR has been conducting business at Will Rogers World Airport for more than 40 years, and we’re extremely proud of our partnership with Oklahoma City and their ongoing investments in the City’s reputation as a great place to do business and live.” AAR’s FBO is the arrival gate for many business people, VIPs and the Oklahoma City Thunder and their opponents. The FBO can accommodate dozens of corporate jets arrivals and departures daily and is often a destination for the USAF jets engaged in training exercises from nearby Vance Air Force Base. In addition, AAR has the fueling contract for the airlines that serve Oklahoma City.

“After the expansion/renovation of the commercial terminal in 2006, it was evident that the airport needed a complimentary general aviation and corporate terminal,” said Mark Kranenburg, Director of Airports. “Our long-time relationship with AAR enabled us to collaborate on this project. The result is a facility that reflects the progressive nature of our community.”

The AAR FBO was built after several years of planning and collaboration with the City’s Department of Airports and the Oklahoma City Airport Trust. Designed by Frankfurt-Short-Bruza Associates, P.C., a nationally recognized design-engineering firm and built by Silvercliffe Construction, both of Oklahoma City, the new facility will serve the needs of both passengers and aircraft crews alike with a number of new amenities. Chip Smith, Director of FBO Services, AAR Aircraft Services — Oklahoma will continue to operate the AAR FBO, bringing more than 30 years of experience serving pilots, passengers and airlines at Will Rogers World Airport.

Will Rogers World Airport is owned by the Oklahoma City Airport Trust and operated by the City of Oklahoma City Department of Airports. Will Rogers is the city’s commercial airport and accommodates over three and a half million passengers each year. The airport is home to nearly 70 tenants and over 10,000 employees. The City also operates and manages Wiley Post and Clarence E. Page Airports.

AAR is a leading provider of value-added products and services to the worldwide aerospace and government/defense industries. With facilities and sales locations around the world, AAR uses its close-to- the-customer business model to serve aviation and government/defense customers through four operating segments: Aviation Supply Chain; Maintenance, Repair and Overhaul; Structures and Systems; and Government and Defense Services. More information can be found at www.aarcorp.com.

This press release contains certain statements relating to future results, which are forward-looking statements as that term is defined in the Private Securities Litigation Reform Act of 1995. These forward-looking statements are based on beliefs of Company management, as well as assumptions and estimates based on information currently available to the Company, and are subject to certain risks and uncertainties that could cause actual results to differ materially from historical results or those anticipated, including those factors discussed under Item 1A, entitled “Risk Factors”, included in the Company’s May 31, 2009 Form 10-K. Should one or more of these risks or uncertainties materialize adversely, or should underlying assumptions or estimates prove incorrect, actual results may vary materially from those described. These events and uncertainties are difficult or impossible to predict accurately and many are beyond the Company’s control. The Company assumes no obligation to update any forward-looking statements to reflect events or circumstances after the date of such statements or to reflect the occurrence of anticipated or unanticipated events. For additional information, see the comments included in AAR’s filings with the Securities and Exchange Commission.

Here’s the latest on this week’s “OStateReport” (published 9/24/15)

The Oklahoma City Airport Trust contracted with Oklahoma City-based Frankfurt-Short-Bruza Associates (FSB) in January 2015 for the design of the expansion. FSB, an architectural-engineering-planning firm, has led the design process, leveraging expertise from partners HOK, a global aviation design leader.

“Our partnership with FSB and HOK will deliver a truly spectacular addition to the airport terminal,” said Mark Kranenburg, airports director with the Oklahoma City Department of Airports.

“We are positioning ourselves as a premier airport that balances passenger security with the customer experience. The new addition will meet that global standard, making Will Rogers World Airport unique compared to other airports across the country.”

The design also calls for the integration of public art installations and for expansive windows and skylights that draw in natural light. Planned interior enhancements of existing spaces include expanded greeter areas and additional seating in the baggage claim area.

This expansion project will provide four new gates, with the ability to add six more gates in the future.

High-tech improvements will enable passengers to receive real-time flight information. A wider concourse will provide a variety of seating options and integrated amenities that meet the needs of today’s traveler.

Courting Younger Generations

OKLAHOMA CITY –

The last time students wandered the halls of the historic Central High School was more than 40 years ago.

But the halls will soon be filled with students again, as the building will be the home of the Oklahoma City University School of Law. The complete renovation of the building is being designed by Frankfurt-Short-Bruza Associates. The building at 800 N. Harvey Ave. was constructed in 1910 and designed by Solomon Layton. It was used as Central High School until 1968, when it was purchased by Southwestern Bell Corp., which occupied the building for a number of years. Oklahoma Farmers Union Mutual Insurance Co. (now American Farmers and Ranchers Mutual Insurance Co.) purchased the building in 2005 and put it up for sale in 2010.

This will be the second Layton project on which FSB has worked. The firm added the dome onto the state Capitol in 2002.

The five-story law school will have a variety of spaces where students can sit in groups and work on projects. Project Manager Fred Schmidt said this capability is a growing trend in education.

“The current generation is much more collaborative,” Schmidt said.

Project Manager Jason Holuby said one of their goals in the design of the renovation is to make every inch of the building multipurpose.

“We want to get the maximum use of the square footage of the building to satisfy the needs of the law school,” he said.

The first floor will feature a combination of a large, open library space and a café. The library will continue onto the second floor, which will serve as the main library space. The floor will also feature a clinical suite where students can practice pro-bono work. The third story will be the grand floor, utilizing the space that was once the theater at the school. While the floor will be dotted with tables and study areas, the furniture can be moved to make way for banquet tables when needed. Two classrooms with 30 seats each will be on the third floor, as well. Faculty offices will be located on the fourth floor, as well as more spaces for students to sit and interact.

“We wanted to encourage that interaction between students and professors,” Schimdt said. “We don’t want that to be scary. We wanted to create a collaborative environment with the faculty and the students.”

The fifth floor will be the epicenter of education. There will be four tiered classrooms with 45 seats each, and two one-level classrooms with 30 seats each. The fifth floor will also feature a courtroom that will be used for regular trials at various times, as well as mock trials for the students. The judge’s bench will be able to seat five judges for mock appeals court trials.

Holuby said the exterior of the building is in better shape than the interior. Some of the interior necessities include changing out the polished brass, bringing in new carpet, and changing the paint colors.

“It will all be a lot of interior work” Holuby said. “The building is in great shape. They really did it up right when Southwestern Bell redid it back in the 1980s.”