In order to create the best possible building for a client, it’s essential to start with the highest quality set of construction documents. When these crucial documents are complete, precise and free of errors, it translates into huge savings, expedited project schedules and a better facility that performs as expected. For FSB, maintaining this level of quality is the result of a multi-step process that requires a strong interdisciplinary team approach, utilizes state-of-the-art computer software and keeps the client informed at every stage of the process.

FSB has a reputation for producing superior construction documents, and our diligence in this area is a key reason why we have a high percentage of repeat clients. Clients generally worry about four things: schedules, cost overruns, change orders and conflicts between any of the interested parties, such as contractor/subcontractor or client/contractor. When you provide thorough, high-quality construction documents, these concerns are addressed right away and worries can be alleviated.

Exceptional documents require exceptional input, which FSB obtains by conducting multiple in-depth design charrettes at the beginning of each project between the firm’s design team, the client and all other important stakeholders. Once the needs and vision for the project are determined and the design process is underway, the client is kept in the loop.

FSB typically reviews design documents with each client at the 15%, 35%, 65% and 95% complete stages, allowing them to see how their input is being integrated into the overall design. Quality documents are obviously easier for the client to interpret, and they allow everyone involved to identify details that need to be changed for functional, budgetary or aesthetic reasons. There are fewer surprises, and clients are much happier on move-in day.

In contrast, if a firm produces construction documents that are incomplete, confusing, or the client does not see them until the 95% completion stage, that client won’t have the extra security of knowing they’re getting what they’ve paid for and may be unsatisfied with the result.

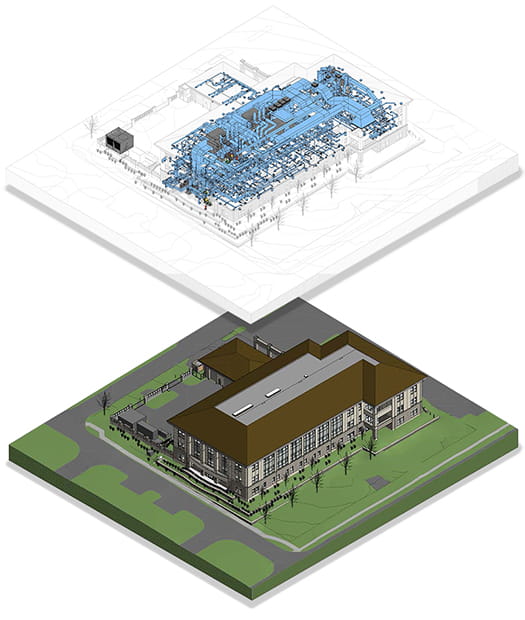

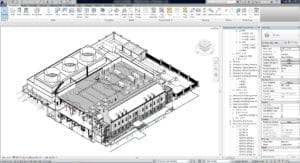

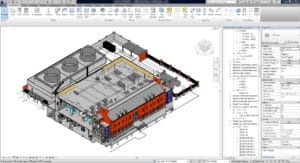

The architects and engineers at FSB utilize cutting-edge design software for their construction documents, including Revit, BIM (building information modeling) and 3-D AutoCAD. The software lets all parties view the designs in real time and identify any spatial or other conflicts. This can be anything from MEP systems that will not fit into a designated space to equipment models that aren’t the right size to operational efficiency issues. Resolving these conflicts during the design stage avoids many costly change orders on the construction site, meaning every dollar spent up front can potentially save multiple dollars in the field.

Quality documents with no omissions or ambiguity are also appreciated by contractors, since they directly correlate to their ability to stay on schedule, keep costs under control and work more smoothly with subcontractors. If there is any ambiguity in a set of documents, contractors typically will add money for any unknowns they see on a set of drawings, boosting the cost of the project. This is where FSB’s document quality makes a huge difference in keeping projects within budget parameters.

To achieve a consistent level of quality, FSB follows very strict quality control procedures for each project and its resulting documents. This includes extensive peer reviews of each facility design by an interdisciplinary team of architects and engineers who are not assigned to that project.

We offer a distinct advantage for clients in this area, since our size and wealth of diverse experience allows FSB to conduct thorough and meaningful QC and constructability reviews during the course of the design. There are many A/E firms out there that do not incorporate the level of detail that we do in our construction documents. It’s a key ingredient in FSB’s success.

To learn more about FSB’s construction document process, contact Laure Majors at busdev@fsb-ae.com or 405.840.2931.

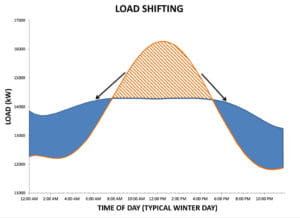

No matter what type of energy-saving steps are initiated, they’re impacted by local geography, climate and weather concerns. FSB’s mechanical and electrical engineering team, with more than 500 years of combined experience, routinely advises clients on power usage for a wide variety of facilities and environments.“Our engineers work all over the world, and every day we are exposed to different types of technology and utility rate structures,” Sauer said. “The art lies in understanding the client’s unique needs and determining which system modifications are the best fit to achieve optimum power savings. As utility rates continue to evolve to a more demand-based structure, it’s important to understand what is driving your peak demand and what steps can be taken to reduce it.”

No matter what type of energy-saving steps are initiated, they’re impacted by local geography, climate and weather concerns. FSB’s mechanical and electrical engineering team, with more than 500 years of combined experience, routinely advises clients on power usage for a wide variety of facilities and environments.“Our engineers work all over the world, and every day we are exposed to different types of technology and utility rate structures,” Sauer said. “The art lies in understanding the client’s unique needs and determining which system modifications are the best fit to achieve optimum power savings. As utility rates continue to evolve to a more demand-based structure, it’s important to understand what is driving your peak demand and what steps can be taken to reduce it.” “That portion of our work has grown every single year,” he said. “It’s become a big part of what we do at FSB. As it’s grown over the years, it really made sense to start a Native-owned architecture and engineering firm.”

“That portion of our work has grown every single year,” he said. “It’s become a big part of what we do at FSB. As it’s grown over the years, it really made sense to start a Native-owned architecture and engineering firm.”

To resolve this problem, several HVAC technologies exist that are suitable for these applications. In-row cooling systems, such as Liebert XD, CRD and APC InRow RC, place cooling systems between the server racks, eliminating the need for a raised floor. FSB has used this system on multiple projects such as a major data center for long-time client The Hertz Company, Sauer noted.

To resolve this problem, several HVAC technologies exist that are suitable for these applications. In-row cooling systems, such as Liebert XD, CRD and APC InRow RC, place cooling systems between the server racks, eliminating the need for a raised floor. FSB has used this system on multiple projects such as a major data center for long-time client The Hertz Company, Sauer noted.

Owners appreciate the vertical lift fabric doors’ ability to seal a space — while vertical lift doors offer significantly less insulation capacity than typical rolling steel doors, they compensate by sealing their edges against air infiltration better than the typical rolling steel door. In many cases the reduction of air infiltration more than compensates for the lower “R” value of the door panels.

Owners appreciate the vertical lift fabric doors’ ability to seal a space — while vertical lift doors offer significantly less insulation capacity than typical rolling steel doors, they compensate by sealing their edges against air infiltration better than the typical rolling steel door. In many cases the reduction of air infiltration more than compensates for the lower “R” value of the door panels. When open, vertical lift fabric doors use no floor space. Unlike rolling steel doors, when the hangar openings are uncovered, the door occupies no floor space because it’s suspended from framing above the door opening. This gives owners more operations flexibility.

When open, vertical lift fabric doors use no floor space. Unlike rolling steel doors, when the hangar openings are uncovered, the door occupies no floor space because it’s suspended from framing above the door opening. This gives owners more operations flexibility. rest of the year they leave the doors wide open for ventilation. For them, it was an advantage to have a vertical lift fabric door that completely pulled up out of the way, so they had the full width and height of that big opening to leave open eight months out of the year. If they had sliding doors, every day they would be moving those doors back and forth to get aircraft in and out.”

rest of the year they leave the doors wide open for ventilation. For them, it was an advantage to have a vertical lift fabric door that completely pulled up out of the way, so they had the full width and height of that big opening to leave open eight months out of the year. If they had sliding doors, every day they would be moving those doors back and forth to get aircraft in and out.” As noted above, the most significant benefits of BIM are its ability to enhance project planning, reduce errors and speed up the construction process. Over the lifetime of the project, each piece of vital information can be attached to the model, where it’s immediately and easily accessible to everyone involved.

As noted above, the most significant benefits of BIM are its ability to enhance project planning, reduce errors and speed up the construction process. Over the lifetime of the project, each piece of vital information can be attached to the model, where it’s immediately and easily accessible to everyone involved. BIM’s usefulness doesn’t end once a building is completed. Clients can use it as a tool to track and plan for needed maintenance throughout the life of the building. It also serves as a huge time-saver for FSB and its many repeats, should they need an expansion or renovation to their facility down the road.

BIM’s usefulness doesn’t end once a building is completed. Clients can use it as a tool to track and plan for needed maintenance throughout the life of the building. It also serves as a huge time-saver for FSB and its many repeats, should they need an expansion or renovation to their facility down the road. “Previously, you could not re-use many of the models made during the life of the project. Preliminary information would need to be manually converted into computer files which would be used as contract documents, and it took time. With BIM, we begin building the model early in the design process, and it continues to grow as more architecture and engineering systems are developed. Once the model is complete, it is an accurate representation of the finished building,” Sauer said. “If a client wants to renovate or add on to the building at a later date, we don’t have to go to the facility and do measurements and assessments and disturb the people working there. When you have a current model, it really minimizes downtime.”

“Previously, you could not re-use many of the models made during the life of the project. Preliminary information would need to be manually converted into computer files which would be used as contract documents, and it took time. With BIM, we begin building the model early in the design process, and it continues to grow as more architecture and engineering systems are developed. Once the model is complete, it is an accurate representation of the finished building,” Sauer said. “If a client wants to renovate or add on to the building at a later date, we don’t have to go to the facility and do measurements and assessments and disturb the people working there. When you have a current model, it really minimizes downtime.”

If you haven’t been in Edmond Public Schools’ Heartland Middle School, you’re missing out on seeing a specially-designed school. Its architect, Frankfurt-Short-Bruza, has received an Outstanding Project award for excellence in educational facility design for spring 2017 from Learning By Design magazine.

If you haven’t been in Edmond Public Schools’ Heartland Middle School, you’re missing out on seeing a specially-designed school. Its architect, Frankfurt-Short-Bruza, has received an Outstanding Project award for excellence in educational facility design for spring 2017 from Learning By Design magazine. “We have accomplished educators leading our vocal music, band, orchestra, drama and visual arts classes,” a spokesperson said. “Our elective wing also features our FACS (Family and Consumer Sciences), Around the World, Enrichment, Tech Lit, and the Gateway to Technology spaces. Science, Technology, Engineering and Math (STEM) are celebrated and encouraged here!

“We have accomplished educators leading our vocal music, band, orchestra, drama and visual arts classes,” a spokesperson said. “Our elective wing also features our FACS (Family and Consumer Sciences), Around the World, Enrichment, Tech Lit, and the Gateway to Technology spaces. Science, Technology, Engineering and Math (STEM) are celebrated and encouraged here!