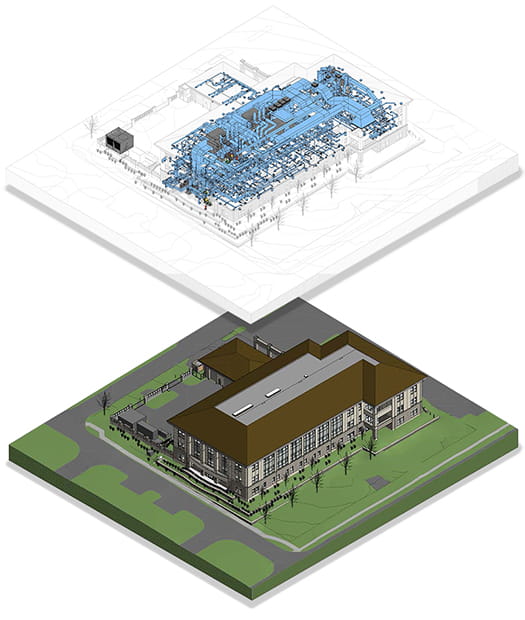

Efficiency and accuracy are essential hallmarks of any successful A/E firm, and at FSB those qualities are greatly enhanced through the use of cutting-edge technology known as “BIM.” Also known as Building Information Modeling, BIM is a very broad term for an intelligent computer model of a building that shows different levels of design and is integrated between all disciplines.

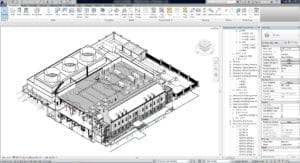

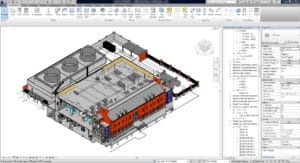

At FSB, the primary tool we use is Revit, which is an intelligent CAD model that allows ‘intelligent attributes’ to be attached to those models. These attributes can include information such as model numbers, capacities and other specific information. Once the BIM information is in there, equipment schedules can automatically and accurately be generated. Those schedules, along with the entire building model, can then be shared with the contractors and subcontractors. This can save them significant time in preparation of cost estimates and also shop drawings.

What that means is that BIM modeling takes designs from traditional 3D to 4D and serves as a platform for project teams and other non-technical stakeholders, who then can more accurately visualize the assembling of a building over time. This ability creates significant benefits for the project, especially when it comes to moving the design and construction phases along swiftly, with better communication between the A/E, Owner and Contractor.

Why Is It Important?

As noted above, the most significant benefits of BIM are its ability to enhance project planning, reduce errors and speed up the construction process. Over the lifetime of the project, each piece of vital information can be attached to the model, where it’s immediately and easily accessible to everyone involved.

As noted above, the most significant benefits of BIM are its ability to enhance project planning, reduce errors and speed up the construction process. Over the lifetime of the project, each piece of vital information can be attached to the model, where it’s immediately and easily accessible to everyone involved.

“Using BIM via Revit means everything can be viewed in real time, as opposed to waiting for weekly meetings or updates from the architect or engineer,” Principal Brian Sauer said. “We can also quickly and easily identify any spatial conflicts or other issues that might crop up, which is a huge time-saver. Any changes that are needed can be made swiftly and at an early stage of the project, so that the impact on the actual construction time is minimized.”

FSB routinely shares its BIM models with contractors and subcontractors, a practice which is highly effective in keeping projects on track, especially if they’re on an aggressive schedule, which is increasingly the case, he said.

“It can save as much as 20% or more of the design and construction timeline for a project, depending upon the complexity of the job,” Sauer added.

The more complex the job, the more time savings there is. For example, the new Oklahoma State Bureau of Investigation Forensic Science Center had a very aggressive schedule. By using BIM, FSB saved about a third in total schedule over similar projects.

Utilizing the Revit software also allows FSB’s architects and engineers to interact with a manufacturer’s website, importing specific information for building components. This information can include exact dimensions, 3-D models and other equipment-specific information that comes directly from the manufacturer. Since FSB does not have to draw these items, time is saved, and accuracy is improved. This specific information is then attached to the BIM model, so contractors know exactly which equipment they need to order. This feature alone is huge as it eliminates many potential errors during the construction process, which translates into fewer construction delays and better cost estimating and cost containment.

BIM’s Benefits are Lasting

BIM’s usefulness doesn’t end once a building is completed. Clients can use it as a tool to track and plan for needed maintenance throughout the life of the building. It also serves as a huge time-saver for FSB and its many repeats, should they need an expansion or renovation to their facility down the road.

BIM’s usefulness doesn’t end once a building is completed. Clients can use it as a tool to track and plan for needed maintenance throughout the life of the building. It also serves as a huge time-saver for FSB and its many repeats, should they need an expansion or renovation to their facility down the road.

“The BIM platform also includes tools that assist us with our calculations,” Sauer said. “Most engineers do a lot of calculations manually, but a well-organized BIM model can greatly expedite certain calculations, such as HVAC loads, duct static pressure calculations and hydronic pressure calculations. A lot of manufacturers also have models of their equipment that will contain attributes necessary to creating equipment schedules, which potentially eliminates a lot of errors when compared to manually entering information.”

“Previously, you could not re-use many of the models made during the life of the project. Preliminary information would need to be manually converted into computer files which would be used as contract documents, and it took time. With BIM, we begin building the model early in the design process, and it continues to grow as more architecture and engineering systems are developed. Once the model is complete, it is an accurate representation of the finished building,” Sauer said. “If a client wants to renovate or add on to the building at a later date, we don’t have to go to the facility and do measurements and assessments and disturb the people working there. When you have a current model, it really minimizes downtime.”

“Previously, you could not re-use many of the models made during the life of the project. Preliminary information would need to be manually converted into computer files which would be used as contract documents, and it took time. With BIM, we begin building the model early in the design process, and it continues to grow as more architecture and engineering systems are developed. Once the model is complete, it is an accurate representation of the finished building,” Sauer said. “If a client wants to renovate or add on to the building at a later date, we don’t have to go to the facility and do measurements and assessments and disturb the people working there. When you have a current model, it really minimizes downtime.”

To learn more about how FSB can help your company, contact Laure Majors at busdev@fsb-ae.com or 405-840-2931.